How to Convert an Inkjet Printer to Sublimation? A Complete Guide

Sublimation printing is a versatile and vibrant method for customizing various products, but it typically requires a dedicated sublimation printer.

However, if you already own an inkjet printer and want to explore sublimation printing without the cost of a new device, it is possible to convert an inkjet to a sublimation printer.

In this comprehensive guide, we’ll walk you through the steps and considerations to make this conversion successful.

Understanding the Conversion Process:

Before you begin, it’s crucial to understand that converting an inkjet to a sublimation printer involves a series of modifications and requires specific sublimation ink and paper.

Sublimation ink is different from standard inkjet ink because it transforms into a gas when heated, allowing it to bond with various surfaces. Here’s how to go about the conversion:

1. Research Your Printer Compatibility

Not all inkjet printers are suitable for conversion to sublimation. Some printers have sealed printheads that make modification difficult.

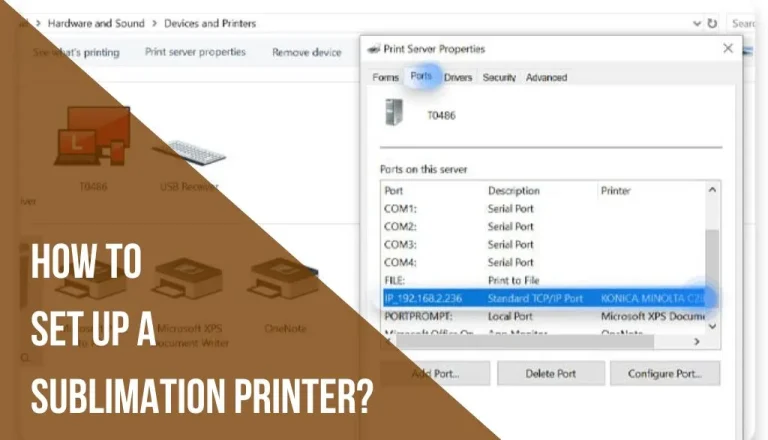

Before proceeding, research your convert inkjet to sublimation printer model to check if it’s compatible with sublimation conversion. Look for guides and forums dedicated to your printer model to see if others have successfully converted it.

2. Gather the Necessary Supplies

To convert your inkjet printer into a sublimation printer, you’ll need the following supplies:

- Sublimation Inks: Purchase sublimation ink cartridges or bulk ink bottles compatible with your printer model. Ensure they match your printer’s color configuration (e.g., CMYK or CMYK+).

- Sublimation Paper: Invest in high-quality sublimation transfer paper designed for sublimation inks. This paper is specially coated to hold sublimation ink.

- Syringes and Needles: You’ll need syringes and needles to fill your printer’s existing ink cartridges or a set of refillable cartridges with sublimation ink.

- Gloves and Safety Equipment: Sublimation ink can be messy, so wearing gloves and protective clothing is advisable. Ensure good ventilation in your workspace as well.

- Printhead Cleaning Kit: You might need a printhead cleaning kit to flush out any residual standard ink from the printhead.

3. Prepare Your Printer

Before converting your printer, ensure it is clean and free of any standard ink residues. Follow these steps:

- Print several pages with your regular ink to deplete the existing ink cartridges.

- Turn off the printer and disconnect it from the power source.

- Remove the existing ink cartridges.

- Use a printhead cleaning kit, if necessary, to clean the printhead thoroughly.

4. Modify or Replace Ink Cartridges

You have two options for adding sublimation ink to your printer:

- Refill Existing Cartridges: Some inkjet printers allow you to refill your existing ink cartridges with sublimation ink. Use the syringes and needles to carefully inject sublimation ink into the cartridges. Be precise to avoid spillage or mixing colors.

- Use Refillable Cartridges: Alternatively, you can purchase refillable cartridges designed for sublimation ink. These cartridges are easier to handle and minimize the risk of contamination.

5. Test Your Printer

After installing the sublimation ink, run a few test prints to ensure the ink flows correctly and that the colors are accurate. You may need to adjust the printer settings to accommodate the sublimation ink’s characteristics, such as color profiles and paper type.

6. Select the Right Sublimation Paper

Sublimation paper plays a crucial role in the printing process. Ensure you use sublimation-specific paper designed to hold sublimation ink and transfer it effectively during the heat press process.

7. Heat Press Process

To complete the sublimation process, you’ll need a heat press machine. Here’s how it works:

- Print your design onto the sublimation paper using your converted inkjet printer.

- Place the printed design face down on the item you want to sublimate, such as a polyester fabric, ceramic mug, or other sublimation-compatible material.

- Use a heat press to apply heat and pressure to the design, allowing the sublimation ink to transform into a gas and bond with the substrate. Follow the recommended time, temperature, and pressure settings for your specific project.

- Once the pressing is complete, carefully remove the sublimation paper, leaving behind your vibrant, custom design.

8. Quality Control and Adjustments

Inspect your sublimated products for color accuracy and vibrancy. You may need to fine-tune your printer settings or color profiles to achieve the best results. Keep in mind that sublimation printing can be sensitive to color management, so be patient and make gradual adjustments.

9. Practice and Experiment

Converting an inkjet printer into a sublimation printer may require some trial and error. Practice on various substrates, experiment with different designs and learn how to optimize your printer for the best sublimation results.

10. Maintenance and Care

Sublimation ink can have a longer shelf life than standard inkjet ink, but it’s essential to use your converted printer regularly to prevent clogging. Perform regular printhead cleanings and ensure proper storage of sublimation ink cartridges.

Frequently Asked Questions:

By using a Canon printer equipped with special sublimation ink cartridges and compatible printer paper, you can achieve vibrant prints on these materials. Sublimation printing from a Canon printer requires special inks that are designed to react to heat.

Convert inkjet to sublimation paper is specifically made to lock in the gas that sublimated ink releases. Regular ink isn’t made to be compatible with sublimation paper, and will usually smear right off the page if you print using this paper.

If you discover that you are not able to find compatible cartridges that contain sublimation inks for HP printers that utilize cartridges with ink. There is no way to transform them into sublimation printers.

Generally, if you’re looking for a cheap way into sublimation printing then the Epson Ecotank range (ET-2803, ET-2760, ET-4760, and ET-15000) is the best.

These use manual refills so you can add sublimation inks rather than stand inks (never fill a printer with anything other than sublimation inks).

Final Verdict:

In conclusion, converting an inkjet to a sublimation printer is a cost-effective way to explore the world of sublimation printing. With the right supplies, careful preparation, and attention to detail.

You can achieve vibrant, long-lasting custom prints on various substrates. Remember that practice and experimentation are key to mastering this conversion process and unlocking the creative potential of sublimation printing.